There´s an old adage first placed on the lips of Sun Tsu, the ancient author of The Art of War.

¨The best defense is a good offense¨

This maxim challenges organizations to stay a step ahead of the circumstances, to be proactive instead of reactive.

From Corefficient’s inception, we set out to create the most efficient cores to power the future, a goal reflected in our name. So, when USA DOE updated the efficiency standards across the Country, asking for near perfection in energy efficiency, it was business as usual for Corefficient.

The Standards

In 1975, the Department of Energy institutionalized the concept of energy efficiency in consumer appliances. By creating regulations for energy efficient cores, the DOE created billions of dollars of energy savings and spurred innovation to meet the country’s inexhaustible demand for energy.

In 2007, the DOE expanded their regulations and set standards for low-voltage, dry-type distribution transformers[i]. In 2010, the regulations were further expanded to include both dry-type and liquid-filled transformers[ii].

Finally, in the latest update to DOE regulation, in 2016 the DOE took the existing regulations and increased transformer efficiency levels.

Copied below are the sections of the Code of Federal Regulations which delineate the new requirements[iii]:

- 431.196 Energy conservation standards and their effective dates.

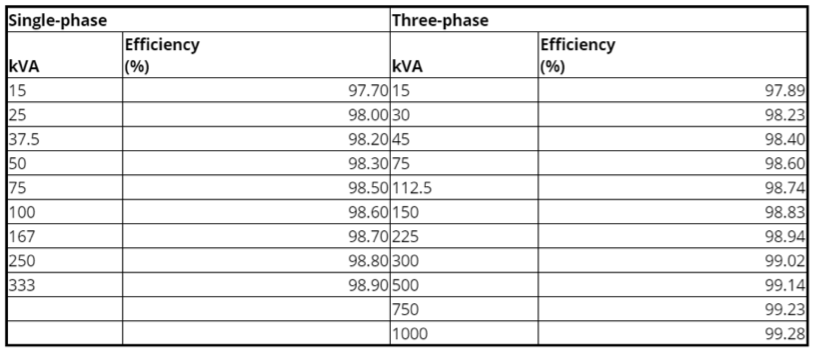

The efficiency of a low-voltage dry-type distribution transformer manufactured on or after January 1, 2016, shall be no less than that required for their kVA rating in the table below. Low-voltage dry-type distribution transformers with kVA ratings not appearing in the table shall have their minimum efficiency level determined by linear interpolation of the kVA and efficiency values immediately above and below that kVA rating.

Note: All efficiency values are at 35 percent of nameplate-rated load, determined according to the DOE Test Method for Measuring the Energy Consumption of Distribution Transformers under Appendix A to Subpart K of 10 CFR part 431.

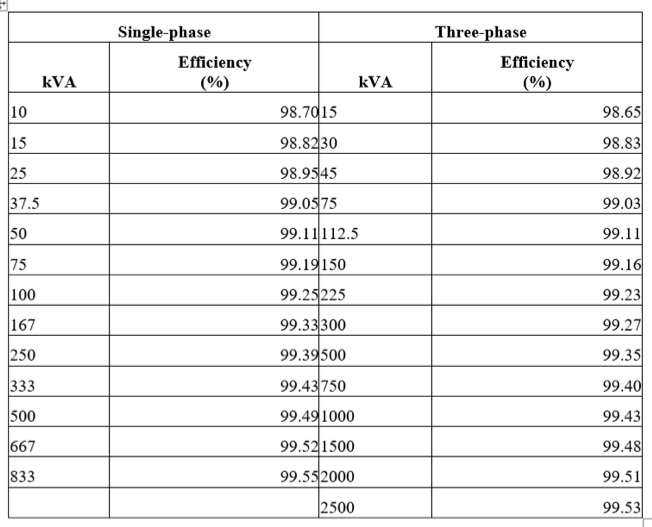

The efficiency of a liquid-immersed distribution transformer manufactured on or after January 1, 2016, shall be no less than that required for their kVA rating in the table below. Liquid-immersed distribution transformers with kVA ratings not appearing in the table shall have their minimum efficiency level determined by linear interpolation of the kVA and efficiency values immediately above and below that kVA rating.

Note: All efficiency values are at 50 percent of nameplate-rated load, determined according to the DOE Test Method for Measuring the Energy Consumption of Distribution Transformers under Appendix A to Subpart K of 10 CFR part 431.

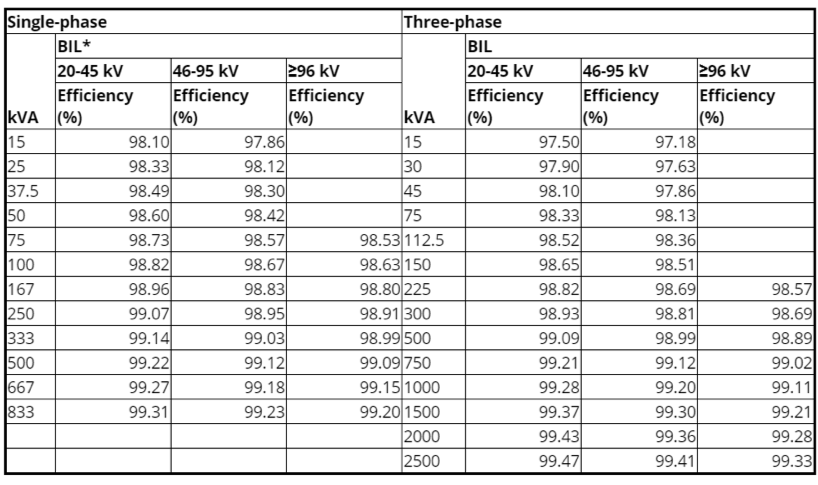

The efficiency of a medium- voltage dry-type distribution transformer manufactured on or after January 1, 2016, shall be no less than that required for their kVA and BIL rating in the table below. Medium-voltage dry-type distribution transformers with kVA ratings not appearing in the table shall have their minimum efficiency level determined by linear interpolation of the kVA and efficiency values immediately above and below that kVA rating.

*BIL = basic impulse insulation level.

Corefficient: Proactive and Ready

To surpass the near-perfect energy conservation outlined by the 2016 DOE regulations, Corefficient implements industry leading practices at every point of the manufacturing process

No stone is left unturned. From electrical transformer materials, to electrical transformer design, electrical transformer manufacturing, and electrical transformer productivity, every aspect of making transformer cores affects the quality of final products. Anything from deviations in thickness, width, material permeability, magnetic properties, chemical composition, to name a few, can cause energy loss in transformer cores.

In order to be offensively minded in meeting regulations, Corefficient has on-site testing. All incoming material is quality tested before use. Finished products are inspected for core loses, permeability, insulation resistance, dimensionality, weight, and sound pollution.

We adhere to DOE, ASTM, and NRCAN regulations and are an ISO Certified Facility.

Our philosophy is to be one step ahead of the game, and we are proud to be compliant with all regulations in order to continue producing the energy efficient transformer core of the future, saving energy, money, and resources for our clients and communities.

About Corefficient

Based out of Monterrey, Mexico, Corefficient’s is a state-of-the-art transformer core company committed to adding value to their transformer core products. Part of the National Material L.P. family of companies, Corefficient specializes in the fields of core engineering, transformer core design, magnetic core expertise, cold rolled steel, grain oriented steel, electrical steel, and – most importantly – customer service.

Visit Corefficient online @ corefficientsrl.com, contact our North America Sales Engineer: 1(704) 236-2510 or call us directly in Monterrey, México: (81) 2088-4000.