As long as human beings roam the earth, energy conservation will remain the key to energy independence. Governments around the world are increasing their investments in renewable energy due to rapid urbanization, industrialization, and increasing demand for transmission. As a result, the electrical transformer core market is experiencing a growth spurt – and high performance cores, energy efficient electrical cores, and grain oriented cores for transformers are in high demand. This means strong developments in the energy sector.

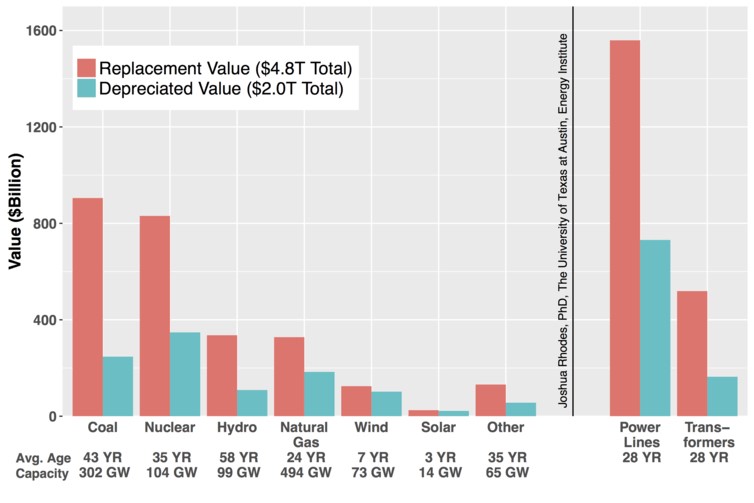

A recent article by UT Austin’s Postdoctoral Researcher of Energy Joshua D. Rhodes Ph.D., talks about recent changes in how American sources our energy. “The oldest generators are large power plants, with many located in the eastern part of the U.S. Most recent additions have been smaller and more spread out – think rooftop solar panels or wind farms. Some experts have even said that this model of more distributed generation closer to where power is consumed – along the edge of the network, rather than central power plants – is the new norm.”

As efficiency regulations become more stringent, demand increases for conventional grain oriented and high permeability electrical steels, and worldwide strategic sourcing becomes fundamental. To meet these demands, companies that deal in transformer core engineering and transformer core manufacturing must either compete or fall behind. The requirement for sustainable, reliable, and affordable energy – along with the need to replace an aging infrastructure will drive new technologies in the power sector well into the future.

See how Corefficient’s proprietary transformer core design and in-house services enable them to compete as a leading electrical transformer core manufacturer. Corefficient has secured sourcing for conventional CRGO, HiNB, and Laser Scribed materials, amongst others. You can also call our sales engineer directly at 1 (704) 236-2510 or email: info@corefficientsrl.com