In a step-lapped miter core, the core steel is miter cut and step stacked in groups of 5 -7 laminations at a time. In this arrangement, the grain orientation of the core steel lines up with the direction of the flux, which then flows parallel with the direction of the grain orientation.

Four main parts make up a dry-type transformer: the core, the coils, the terminals and the structural frame. The core’s job is to provide a path for the magnetic flux where the windings are linked, transferring energy from the primary winding to the secondary winding. When voltage is applied to the primary, current flows producing a magnetic field, or flux. Secondary voltage is induced due to the coupling of the secondary to the magnetic field.

Energy is required to magnetize the core. The amount of energy required depends on the composition of the core material, joints or air gaps within the core and the type of core construction. The four main types of core construction are wound cores, stamped laminations, butt-lapped cores and step-lapped miter cores.

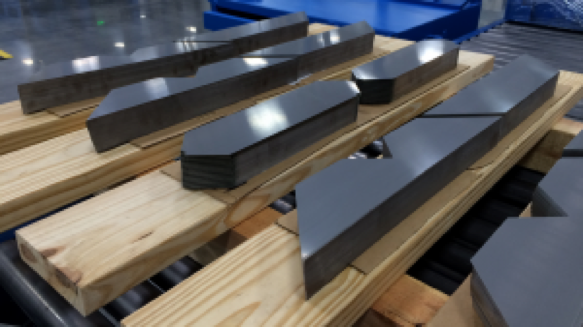

Corefficient’s GEORG brand TBA lines are able to handle material from 2 to 17 inches wide and a thickness of .009 to .014 inches. With high speed, fully automated precision cutting and stacking lines we are able to meet our customers’ needs in a timely manner; either as logs or fully assembled cores.

Corefficient houses 3 GEORG Precision Cut TBA 400 STA/B (5) machines equipped with various longitudinal adjustable notches and shears for highest output. The STA/B stacker system will stack the laminations to accurate leg and yoke logs in full sequence in line.

In addition to the Precision Cut TBA 400 STA/B (5) machines, Corefficient also houses a GEORG Step Lap Lamination Cutting Line TBA 400 ECOLINE equipped with a special STA-stacking system which enables the accurate stacking of the cut laminations via threading pins. The leg logs are stacked in the line and only the top and bottom yokes are inserted manually at a later stage. Compared to the stacking concept layer by layer the core building time will be reduced considerably.

Corefficient also provides a frame with each transformer core, whether designed and supplied by Corefficient or the customer.

More About Corefficient

Part of the National Material L.P. family of companies, Corefficient specializes in the fields of core engineering, transformer core design, magnetic core expertise, cold rolled steel, grain oriented steel, electrical steel, and – most importantly – customer service.

Contact Corefficient’s sales engineer today at: 1 (704) 236-2510.