What comes to mind when you see the word “pollution”?

Does it evoke images of clouds of smog hanging over a city’s skyscrapers? A sewage plant, perhaps. Oil spills, floating, plastic islands in the ocean, litter on a beach… these are the typical examples that come to mind.

But what about the blaring horns and engine noises during rush-hour traffic? The sound of airplanes flying above?

Noise pollution is a major problem in cities around the world, and improper management of it is known to be detrimental to the health of humans and animals. It can cause stress, interrupt sleep, and disturb people throughout the day.

Because of this, today’s engineers are obsessed with finding new ways to reduce pollution in their products – both for economic and environmental reasons – including noise pollution.

The electrical transformer core industry is no exception. Increases in transformer performance are known to increase noise level, so engineers must employ a variety of noise reducing measures to lower the devices’ operating noise.

Why do electrical transformers make noise?

That familiar hum you hear when you approach a transformer unit is primarily caused by the periodic mechanical deformation of the transformer core and the winding coils, which are affected by the fluctuating electromagnetic flux within.

Noise is also caused by the vibrations of the chassis’ walls and the magnetic shunts that hold them in place. Loose shunts can cause rattling.

How can noise be reduced?

Certain methods are tried-and-true, such as stiffening the bracing and supporting parts, or adding additional cushion between different parts of the transformer. Sound proofing and barrier walls have also been employed.

Other solutions include:

- Reduction in core flux density

- Increased core damping

- Use of step-lap joint

- Use of sound insulation panels between tank stiffeners

- Use of double tank design

Our noise measurement facilities at Corefficient

To properly test the noise levels of an electrical transformer, the proper environment must be used.

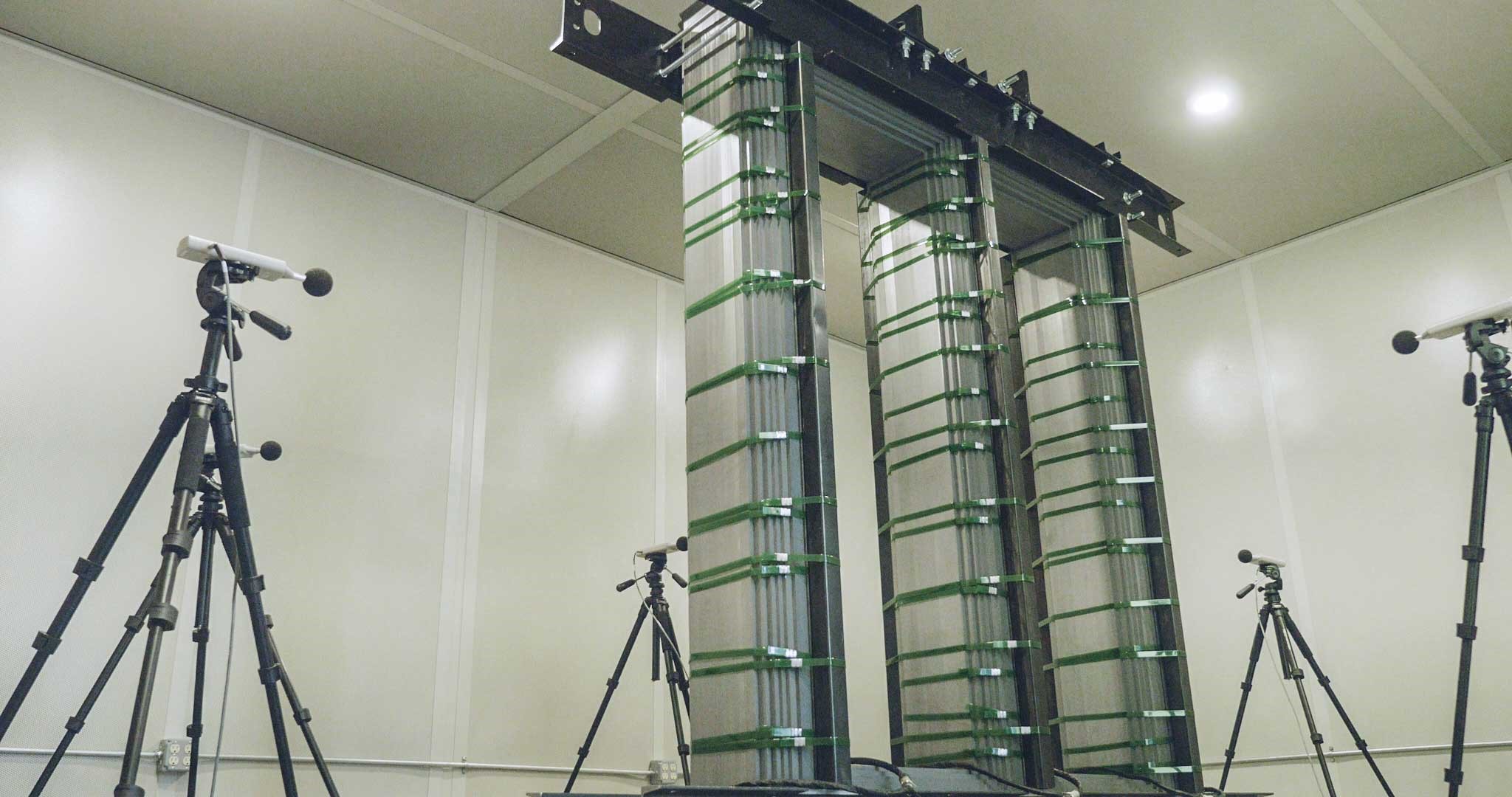

At Corefficient, we use a special, soundproofed room that has an ambient sound pressure level that is 5db below the sound pressure of the transformer. Inside, we use a variety of high-sensitivity microphones to detect even the most minute noises emanating from the transformer.

Committed to quality

Corefficient’s state-of-the-art facility based out of Monterrey, Mexico is a transformer core company committed to adding value to their transformer core products. Combining experience and success in the fields of transformer core engineering, transformer core design, magnetic core expertise, cold-rolled steel, grain oriented steel, electrical steel, and – most importantly – customer service.

Contact Corefficient’s sales engineer today at: 1 (704) 236-2510