A power surge is hazardous. This is common knowledge. One errant lightning strike and the interior of your preferred gadget will melt into a useless goo. Although power plants cannot produce the same amount of electricity as a single lightning strike—a billion volts—they create more energy than your appliances can use. How does all that electricity arrive at your house at the ideal voltage? The enchantment of electrical transformers holds the key. For distribution and end-consumption purposes, transformers can convert voltages either up or down.

It has taken decades for transformer core designs to evolve and improve since the invention of the first step-down transformer in 1878. By adding copper wiring to this basic iron ring, engineers produced an electrical device that is now essential to modern economies. With a focus on the modern-day transformer, Corefficient works to support its clients creating designs that maximize electrical efficiency, physical space, thermal requirements, and cost. Transformer core production is adapted to customer needs and accommodates a wide range of customer end-use applications.

As technology evolved, the emphasis shifted from creating the sizeable and most proficient transformer cores to satisfying customer demands. The D.O.E. efficiency standards of today demand that designs meet and frequently surpass core loss predictions. Businesses must review their current plans and upgrade or eliminate electrical losses to produce energy-efficient cores.

How can you produce a transformer with the required efficiency while keeping costs down and meeting all the specifications for power, electrical standards, physical space, and heat rise? For Corefficient, the solution is clear: core design!

How Corefficient Transforms Core Design into Cost-Effective, High-Efficiency Transformers

When it comes to achieving the most efficient transformers while still meeting stringent power requirements and other electrical standards, Corefficient offers customers a proven approach. Our electrical engineers are experienced in anticipating all the variables associated with power transformer design, allowing us to create a transformer that meets a customer’s needs.

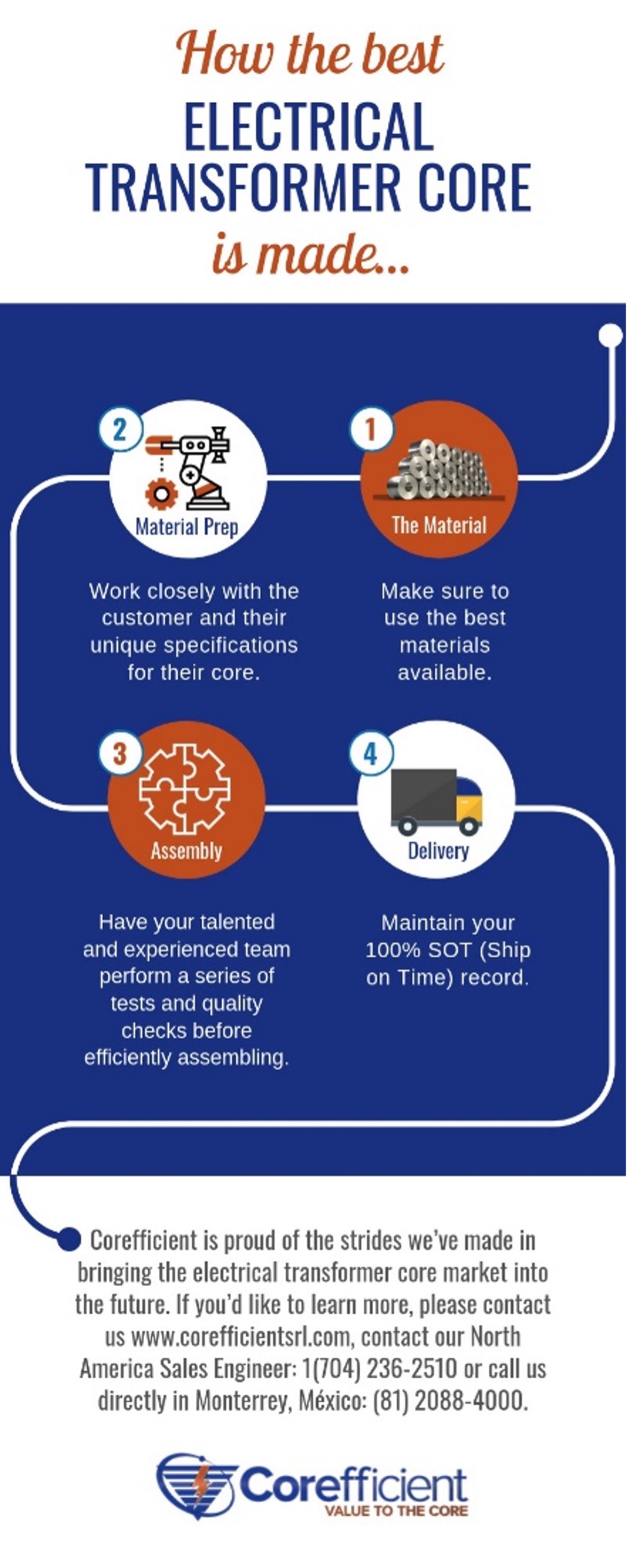

Raw materials’ acquisition is the first step in Corefficient’s value-added proposal. We can provide customers with the quickest lead times because of a strategic alliance with a steel service facility a few miles away. We also thoroughly test each raw material in our on-site laboratory for size, permeability, and core loss.

The steel undergoes numerous testing stops throughout the manufacturing process as it makes its way toward becoming energy-efficient transformer cores to guarantee core integrity. Naturally, the finished products also go through thorough transformer core testing.

After covering the fundamentals of high-quality electrical steel, transformer core design, supply, and optimization become vital. Corefficient is committed to offering our customers a competitive edge by producing electrical transformer cores that consistently surpass client expectations for quality, delivery, and value.

Corefficient: Transformer Core Expert with a Green Mindset

Transformer core efficiency is now more than just a possibility to save energy and money; it also has to do with building a sustainable future as the globe develops and places more emphasis on green energy. Transformers are responsible for minimizing loss while using renewable energy as a source. The transformer core design needs to be changed to accommodate two-way currents, active energy measurements, and energy storage units that will eventually be a component of the energy grid as the grid becomes more decentralized and advanced.

Since the beginning, the sole purpose of our company has been to conserve the energy derived from natural resources. Corefficient’s transformer cores save North American consumers billions of dollars while minimizing the non-favorable environmental effects of their energy usage.

Making transformer cores with a green mindset takes no shortcuts to energy efficiency, which is another reason we ensure every product that leaves our plant must be of the utmost quality.

Combining expertise and experience in cold rolled steel, grain-oriented steel, electrical steel, transformer core engineering, transformer core design, and — most importantly — customer service, Corefficient’s cutting-edge facility in Monterrey, Mexico enhances the value of their transformer core products.

At Corefficient, we take pride in combining our expertise in transformer core design with our high standards and cost-effective services to ensure total customer satisfaction. Contact us today to start building the most efficient and durable power transformer currently on the market.

More About Corefficient

The highest level of customer information confidentiality is a priority for Corefficient, a wholly independent company. We have an ideal combination of young and experienced professionals, with a state-of-the-art facility and our location as a market reference for sustainable advantages. Whatsmore, we strive for excellence in every aspect of our operations and being fully ISO-9001 certified is just one way we do it.

Corefficient places a high importance on openness, honesty, respect, and teamwork, as well as self-improvement and compliance. In addition, we implement procedures that encourage ownership, responsibility, accountability, and cooperation. Through an organization built on methods, our guiding principles are safety, quality, and productivity.

Visit Corefficient’s online contact page or call (704) 236-2510 to speak with Corefficient’s North American sales engineer now – we’d love to speak with you!