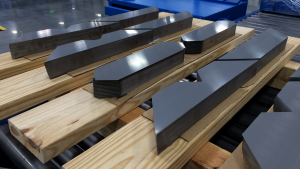

Transformer Cores

STEP LAP FULL MITRE Cores

Our GEORG brand TBA lines are able to handle material from 2 to 17 inches wide and a thickness of .009 to .014 inches. With high speed, fully automated precision cutting and stacking lines we are able to meet our customers’ needs in a timely manner; either as logs or fully assembled cores. To further enhance our position in the market, we will provide a frame with your transformer core, whether designed and supplied by Corefficient or the customer.

Materials

As efficiency regulations become stricter, demand increases for conventional grain oriented and high permeability electrical steels, and worldwide strategic sourcing becomes fundamental. To meet these demands, Corefficient has secured sourcing for conventional CRGO, HiNB, and Laser Scribed materials, amongst others.

DISTRIBUTED GAP Cores

Corefficient is committed to offer the most efficient wound cores in the industry, with DG Cores built to customer specifications on our TRANCO and AEM Unicore brand machines; whether single phase or three phase designs. Our TRANCO lines are able to handle material from 3.0 up to 10.5 inches wide, and a thickness of .007 to .014 inches. Our AEM lines are able to handle material from 1.18 up to 16.7 inches wide, and a thickness of 0.007 to 0.014 inches.