How Transformer Core Mechanisms Impact Performance

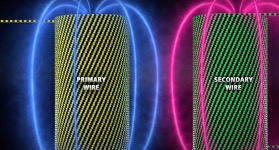

We must first understand how transformer cores operate to ensure high transformer core performance and safety. A transformer is a static electrical device that transfers electrical energy between two or more circuits. A varying current in one coil of the transformer produces a varying magnetic flux, which, in turn, induces a varying electromotive force (EMF) or “voltage” across a second coil wound around the same transformer core. Electric power can be transferred between the two coils without a metallic connection between the two circuits. Faraday’s law of induction, discovered in 1831, described the induced voltage effect in any secondary coil due to changing magnetic flux cutting it.

It is also important to assimilate the design of a transformer, which includes 3 types: core electrical transformer, shell electrical transformer, and auto electrical transformer. The differences in how the windings are wound around each transformer core is what categorizes each type. The windings are electrically connected in auto transformers, and the other two are not electrically connected.

To put it simply, transformers are used to increase or decrease the alternating voltages in electric power applications. They are devices that step-up or step-down the voltage of an electrical supply. To reduce transmission losses, utility companies transmit electricity at high voltages across buried or overhead wires, and a transformer decreases this voltage to make it suitable for household use. And when this process fails, it can fail magnificently, which is why there is nothing more important to an electrical transformer core manufacturer than ensuring the safety of the core.

Transformer Core Construction at Corefficient

The magnetic flux distribution in the transformer core, and particularly at the joints, has a considerable influence on efficiency losses. This is the reason why Step Lap Full Miter (SLFM) stack core designs superseded designs which use rectangular joints. Also this new arrangement, in particular yokes with “V” notches for the center leg, allows for less core steel; meaning a considerable cost reduction of the final transformer.

Coefficient’s Top of the line GEORG brand TBA lines are able to handle material from 2 to 17 inches wide and a thickness of 0.009 to 0.014 inches. With high speed, fully automated precision cutting lines we are able to meet our customers’ needs in a timely manner; either as logs or fully assembled cores with our stacking lines.

On the other hand, Distributed Gap wound cores – also known as DG Cores – are popular in the distribution transformer industry. These cores have few joints so they can carry the flux nearly uninterrupted by gaps making a smoother transition over the cut region. They offer excellent performance with the added benefit of a very simple clamping structure and assembly process, often utilizing 75% fewer components than an equivalent stacked core.

Corefficient has Tranco and AEM Unicore machines for either single phase or three phase designs. Tranco lines can handle material from 3 up to 10 ½ inches wide, and thickness of 0.007 to 0.014 inches. AEM lines go from 1.18 up to 16.7 inches wide, and thickness of 0.007 to 0.014 inches. Of course, a fundamental step for any wound core in order to ensure performance of grain oriented steel materials is annealing. Corefficient invested in a modern rolling hearth annealing furnace (continuous) to relieve stresses induced through core manufacturing, and return the steel to original properties.

What Circumstances Contribute to the Safety of an Electrical Transformer?

-

Proper specifications

- Proper type of insulation

- Correct capacity

- Appropriate installation location (ie: dry environment, perfect temperature, etc.)

-

Reliable facilities

- Impeccable installation

- Proper protection for switch and relay

- Accurate capacity and protection range of lightning

-

Strict operation & ongoing maintenance of the equipment, such as:

- Insulation oil

- Voltage in the facility

- Load in the cable connections

- Accessories care

- Monitoring for loose parts/heated parts upon conducting

- Arrangement of the protection circuits

- Inspection of the gaskets, electrical wire, and valves

- Mechanical & Technical Updates

- Refurbish older transformers

- Awareness of evolving manufacturing practices and transformer design innovation

Successful care of electrical transformers requires regular, careful inspection and detailed maintenance. Thanks to highly efficient technology, advanced transformer protection systems, and extensive pre-testing performed on various transformer parts including the transformer core, transformer safety is absolutely attainable. And, as time rolls on, we can be certain that electrical transformer technology will continue to evolve.

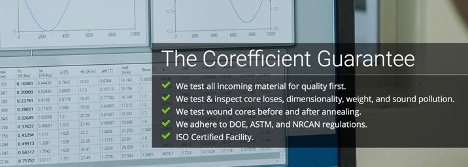

About Corefficient & Our Approach to Designing the Best Electrical Transformer Cores

Corefficient designs, manufactures, and markets energy-efficient electrical cores; a major component used in the manufacture of dry-type and liquid-filled transformers. Offering a variety of transformer core services from sourcing transformer materials in-house and supplying a finished transformer core, Corefficient is proud to be a global competitor in electrical transformer core manufacturing and top electrical core supplier.

ANNEALING:

To ensure the performance of grain-oriented steel materials, Corefficient has invested in a modern rolling heart annealing furnace (continuous) to relieve stress induced through core manufacturing, and return the material to its original properties.

PAINTING:

Cores are delivered in a number of finishes to promote greater electrical and heat insulation, as well as corrosion protection. To fulfill diverse customer needs, we have an on-site, dedicated paint booth facility to paint and coat cores to our customers’ specifications.

TESTING:

Corefficient has a complete, on-site quality control laboratory to test and verify raw materials, with in-line testing of finished cores, to verify that your cores meet specifications. As an option upon request, we can provide both simple and engineering reports including saturation and sound curves.

Visit Corefficient online @ corefficientsrl.com, contact our North America Sales Engineer: 1 (704) 236-2510 or call us directly in Monterrey, México: (81) 2088-4000.

A special “thank you” to Jeson Pitt and his excellent writings we used for reference on our article.