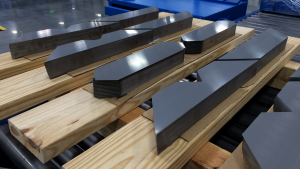

The magnetic flux distribution in the transformer core, and particularly at the joints, has a considerable influence on efficiency losses. This is the reason why Step Lap Full Miter (SLFM) stack core designs superseded designs which use rectangular joints. Also this new arrangement, in particular yokes with “V” notches for the center leg, allows for less core steel; meaning a considerable cost reduction of the final transformer.

The magnetic flux distribution in the transformer core, and particularly at the joints, has a considerable influence on efficiency losses. This is the reason why Step Lap Full Miter (SLFM) stack core designs superseded designs which use rectangular joints. Also this new arrangement, in particular yokes with “V” notches for the center leg, allows for less core steel; meaning a considerable cost reduction of the final transformer.

Coefficient’s Top of the line GEORG brand TBA lines are able to handle material from 2 to 17 inches wide and a thickness of .009 to .014 inches. With high speed, fully automated precision cutting lines we are able to meet our customers’ needs in a timely manner; either as logs or fully assembled cores with our stacking lines.

On the other hand, Distributed Gap wound cores – also known as DG Cores – are popular in the distribution transformer industry. These cores have few joints so they can carry the flux nearly uninterrupted by gaps making a smoother transition over the cut region. They offer excellent performance with the added benefit of a very simple clamping structure and assembly process, often utilizing 75% fewer components than an equivalent stacked core.

Corefficient has Tranco and AEM Unicore machines for either single phase or three phase designs. TRANCO lines can handle material from 3 up to 10 ½ inches wide, and thickness of .007 to .014 inches. AEM lines go from 1.18 up to 16.7 inches wide, and thickness of 0.007 to 0.014 inches. Of course, a fundamental step for any wound core in order to ensure performance of grain oriented steel materials is annealing. Corefficient invested in a modern rolling heart annealing furnace (continuous) to relieve stresses induced through core manufacturing, and return the steel to original properties.

More About Corefficient

Corefficient is a premiere transformer core manufacturer committed to adding value to our transformer core products. Part of the National Material L.P. family of companies, Corefficient specializes in the fields of core engineering, transformer core design, magnetic core expertise, cold rolled steel, grain oriented steel, electrical steel, and – most importantly – customer service.