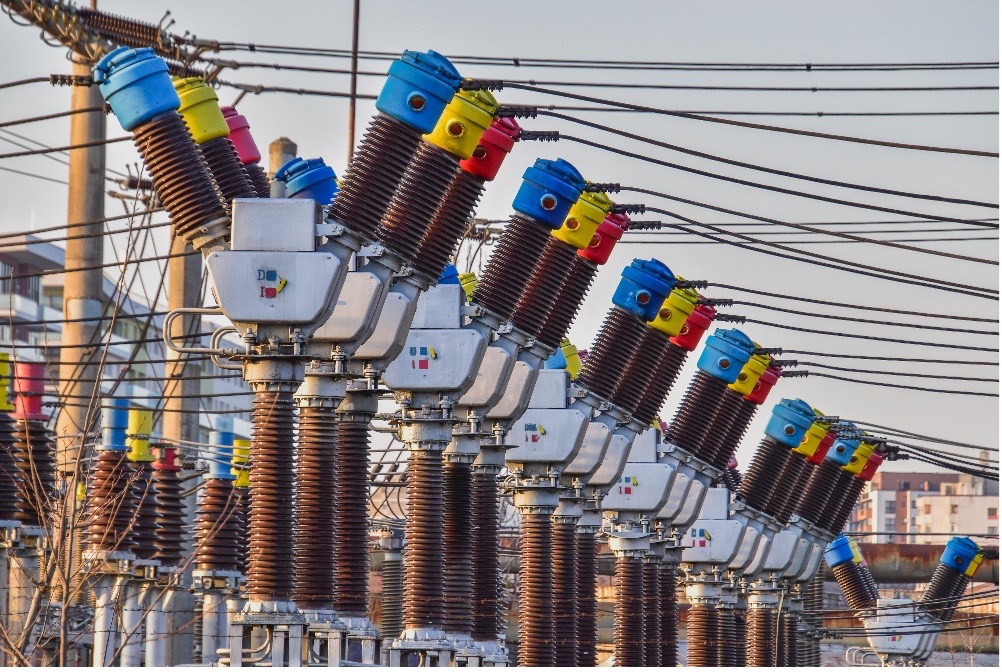

Emerging technologies in the transformer core and electrical transformer industry are on the rise. With a predicted CAGR of 4.3% from 2020-2030, the worldwide transformer core market size is expected to increase from its estimated value of $8.9 billion in 2020 to $13.5 billion by 2030. Transformers are arranged according to their type and capacity. Additionally, the primary, secondary, or tertiary windings used in their cores come in different grades. A low-reluctance magnetic channel that passes through all the windings is referred to as the transformer core. It helps boost the transformer’s efficiency. The flux linkages between a transformer’s core windings determines its efficiency.

The rapid industrialization and urbanization of the world’s cities, along with the recent increase in government funding for renewable energy initiatives, have significantly increased the market for transformer cores. As a result, the market expands as the number of power transformers increases.

There is an increased usage of renewable energy sources. Plus, there is rising global demand for electricity production. Collectively, these are the main factors driving the expansion of the transformer core market. However, the core has a high consumption of copper wires making transformer cores high cost. This might serve as a market restraint because they are prohibitively expensive.

The transformer cores used in distribution transformers will likely decline due to increased power grid construction and power generation projects, which drive the overall number of power transformers. In addition, compared to the oversaturated markets of North America and Europe, Asia-Pacific is expected to experience tremendous growth. Considering this, we have gathered the newest emerging technologies exclusively for you.

First Swarm Satellite Connected Transformer in the World

Emerging Technologies in New Zealand

Dynamic Ratings and ioSphere IoT have developed the first Swarm Technologies satellite-connected transformer to reach the grid’s most outlying areas. Situated in the world’s most well-known technological testbed (New Zealand), this project is perched on the edge of the Canterbury Plains. IoSphere IoT and Dynamic Ratings worked with Electricity Ashburton to connect one of its transformers to the ConnectGrid cloud via the Swarm satellite network. You may check their case study to learn more about this project.

These traditional communications networks are entirely cut off from several crucial network assets located outside their range, such as this one. To monitor their status and condition, one may have to travel a significant distance. One may even take a helicopter to isolated locations. As the network gets busier and under more demand, access to important operating characteristics (such as temperatures and loads) becomes more critical. Many remote assets are frequently not covered by cellular or standard WAN networks. This makes operation and management more challenging and expensive.

It is easy to obtain routine data downloads from equipment such as transformer monitors, online DGA, distribution network equipment, and nearly any system to expand the visibility of the network for operational and maintenance purposes, as this technology illustrates.

Nynas Releases Premium Circular Transformer Fluid

Emerging Technologies in Sweden

One of the world’s top producers of naphthenic oil, Nynas AB, recently unveiled NYTRO® RR 900X. It is a circular transformer fluid built on the most potent and efficient re-refining technology. Today, most industries significantly focus on sustainable development, and Nynas is no exception. The company gives utilities and OEMs a chance to participate in the circular economy. They help meet greenhouse gas reduction goals by introducing NYTRO® RR 900X.

The NYTRO® RR 900X’s outstanding performance makes it appropriate for various electrical applications, including high voltage and high-power transformers. According to the IEC 60296 standard, mandates require all feedstock for re-refined fluids come from power equipment. The new grade complies with this requirement. Compared to virgin transformer oil, NYTRO® RR 900X delivered at least a 70% reduction in greenhouse gas emissions throughout its lifetime at a 100% recycling rate.

According to Nynas’ Sustainability Manager, Marika Rangstedt, “replacing one unit of virgin transformer oil with NYTRO® RR 900X also means savings in crude consumption, crude being a finite resource. We are very proud of our contribution to the reduced environmental footprint of transformer oil production.”

To lessen the effects of transportation-related pollutants, NYTRO® RR 900X will be offered in Europe only.

Global Clean Energy Action Forum: Accelerating the Transition to Clean Energy

Emerging Technologies in the United States

Global energy leaders gathered in Pittsburgh on September 21–23, 2022, for the Global Renewable Energy Action Forum to discuss practical strategies for accelerating the switch to clean energy and combating climate change.

Rapid Innovation and Deployment

The forum’s “Rapid Innovation and Deployment” topic put the need for a clean energy transition front and center. It is the focus in discussions and events concentrated on fostering greater cross-national and cross-sectoral cooperation to commercialize climate solutions.

World leaders discussed nuclear energy expansions to build low-carbon energy markets and employ zero-carbon fuels. How to implement carbon capture technology faster was a topic. As well as, how to push an energy transition that maintains and creates jobs was part of high-level panel discussions. They also gave special consideration to energy security, employment, and affordability.

Cutting-edge Research Facility for Sustainable Practice Demonstrations

Before the public event began on Thursday afternoon, GCEAF delegates visited Mill 19, a former steel mill that is now a cutting-edge research facility influencing the future of advanced manufacturing and sustainable practices. Guests took part in many manufacturing and sustainable practices demonstrations as part of the tour:

- The Carnegie Mellon University School of Architecture’s Azadeh Sawyer, an assistant professor of building technology, demonstrated how she is utilizing virtual reality to promote green construction practices, enabling clients to investigate how various design components affect the user experience and energy efficiency.

- Compared to conventional production techniques, Sandra DeVincent Wolf, executive director of CMU’s Manufacturing Futures Institute (MFI), suggested a waste-free, affordable, and energy-efficient robotic wire arc additive manufacturing process.

- Participants were shown by the Advanced Robotics for Manufacturing (ARM) team how a robotic arm can rapidly and effectively check intricate turbine blades for flaws.

More Innovations in Energy

Pittsburgh-based energy and climate technology entrepreneurs presented their cutting-edge technologies to a panel of industry experts and venture capitalists. The DOE’s Office of Technology Transitions served as the event’s host, and many of the organizations that participated were spun out from or directed by CMU teachers or graduates. Their innovations include:

- Finished power electronics components (inductors and transformers), made by CorePower Magnetics, using cutting-edge manufacturing techniques and materials to function with excellent temperature stability.

- A biomass system called Farm to Flame Energy enabling the smokeless and odorless burning of various agricultural wastes.

- A startup called Integrated Silicon Technologies created a ground-breaking continuous method that can halve the price of silicon-based solar power.

Paulina Jaramillo, a professor of engineering and public policy (EPP) at CMU and co-director of the Green Design Institute, moderated a panel discussion on the just-launched Open Energy Outlook (OEO). This project examines U.S. energy futures to guide energy and climate policy initiatives by utilizing the highest standards of policy-focused theoretical modeling, maximizing transparency, and creating a networked community. An EPP Ph.D. student, Katie Jordan, presented the team’s methods and results. The Wilton E. Scott Institute for Energy Innovation at CMU, in collaboration with North Carolina State University and with financial support from the Sloan Foundation, launched the OEO.

“Efficient” is Part of Our Name

Our ability to progress in the direction of efficiency and the minimization of energy losses during electrical transfer with energy-efficient cores has been made possible by our comprehension of the current environmental situation. All power must pass through transformers and selecting an energy-efficient core is the best method to minimize energy loss. We exercise conservation by making energy-efficient transformer cores and prudent infrastructural decisions, such as ensuring that the companies that manufacture the products utilized in our electricity system are concerned about the environment. It is also why Corefficient pays attention to emerging technologies in the transformer core industry.

Corefficient tests its materials throughout the manufacturing process to produce cores with improved efficiency. From the time it enters the factories as raw material until it reaches the latter stages of building DG-wrapped cores, its magnetic flux, permeability, resistance to surface insulation, and consistent widths and thicknesses are all examined. A better cooling medium that minimizes energy loss and thinner or domain-refined materials are all products of Corefficient’s quality control laboratories located inside the manufacturing facilities.

About Corefficient

Energy-efficient electrical cores are created, produced, and sold by Corefficient. Corefficient, based in Monterrey, Mexico, offers the transformer core market the value of experienced people, latest technology, and financial strength. The organization is excited to create a new legacy of value from the ground up, and our goal is to ensure the continual delivery of excellent service. Call Corefficient’s North American sales engineer at (704) 236-2510 if you’re looking for revolutionary transformer core components to fulfill rising energy standards.