Everyone knows the dangers of a power surge. One misplaced lightning bolt, and suddenly the inside of your favorite device turns into a melted blob of useless.

While power plants do not generate the one billion volts delivered by a single lightning strike, they still create much more energy than your appliances can handle. How does all that power get into your home at just the right voltage? The answer is the magic of transformers. These devices can convert voltages up or down to meet distribution and end-consumption needs.

The Role of Transformers

When coal, gas, water, nuclear, wind, or solar plants create electricity all over the world, they send it to a transmission grid which is then connected to a distribution grid.

At each connection, the voltage is manipulated by transformers. First, transformers step-up the voltage so that it will travel efficiently. Then, they step-down the voltage for distribution grids to meet urban safety standards. Finally, the energy is again lowered as it enters your home’s breaker box.

The Importance of Electrical Transformer Core Design

Because so much electricity gets channeled through transformers, small improvements in efficiency translate into huge savings.

As the world focuses on the environment and energy conservation, a new layer of significance has been placed on transformer efficiency. These new concerns were embodied in the DOE’s updated 2016 transformer energy conservation standards.

The near-perfect conservation rates demanded by the regulations can be met by focusing on the best transformer core design. Energy efficient cores made with quality materials and precise manufacturing drive quality transformer performance.

How to Make the Best Transformer Core

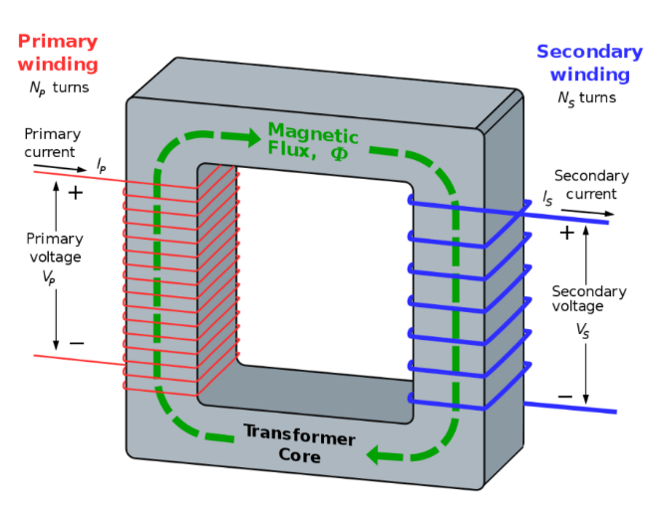

In its simplest form, transformer core is composed of two or more coils of insulated wire wound around a laminated steel core. The magnetic field created between the two wires transfers the current from one wire to the other.

The first step to making the best transformer core is tailoring its design to the end-need. The four main types of core construction are wound cores, stamped laminations, butt-lapped cores, and step-lapped miter cores. Within each of these, materials and configurations can vary. Professionals in the industry can help consumers decide which is the perfect core for their needs.

Once the core design has been decided, materials are ordered. Cores can be made from several different materials including amorphous steel, solid iron core, amorphous metals, ferrite ceramics, laminated magnetic cores, carbonyl iron cores, and silicon steel.

After the materials have been approved, they are cut by highly specialized machines. Finally, they are assembled and prepared for any further service, such as annealing or painting.

The Corefficient Advantage

By testing at every step of the process, Corefficient assures the best transformer cores. Corefficient applies Epstein, Single Sheet, Franklin, and Dimensional testing. From material thickness to insulation resistance and permeability, the materials and finished products leave the factory with a stamp of approval. That’s the Corefficient service.

Corefficient understands the details that create core value and longevity in cores. Every step matters starting with material selection, to geometries, and through the manufacturing processes. Through this drive for perfection, and by protecting customer confidentiality, Corefficient equips its customers with cores capable of meeting tomorrow’s energy needs.

About Corefficient – Corefficient is a leader in the electrical transformer core market by consistently fulfilling the needs of our customers through operational excellence and product innovation, the needs of our employees through development, and the needs of our shareholders through financial stewardship.

Visit Corefficient’s website today: https://corefficientsrl.com/ Contact our North America sales engineer at 1 (704) 236-2510, our Monterrey, México office (81) 2088-4000, or toll-free in the USA: 1 (844) 202-1226.