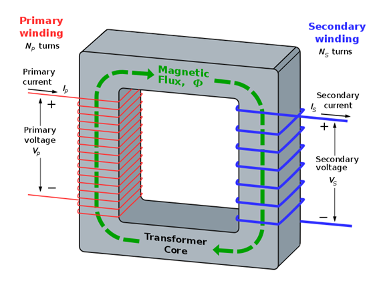

The electrical transformer is one of the most critical inventions in electrical engineering. A voltage regulator, invented in the 1830s by Ottó Bláthy, Miksa Déri, and Károly Zipernowsky, changes voltage levels in an electrical system to suit changing energy demands. Today’s transformers are complex systems with multiple components working together at high speeds to achieve their full potential. But what exactly makes them work so well? Visibility, traceability, and accountability in energy efficient transformer cores is important.

Engineers confronted a challenge a few years ago: how could we increase the efficiency of the transformer cores that are already in use so that they can continue to provide the necessary power for our society? You may have heard that engineers are trying to figure out how to make existing transformer cores more efficient to deliver the energy our society needs.

To solve these problems, engineers spent many years developing new materials and designs that would help reduce costs while at the same time maintaining or improving upon performance metrics such as power density, efficiency, and reliability.

Complex cores have been challenging to develop because they must operate at various frequencies and make good electrical and thermal connections. The challenge for designers is incorporating more compact designs with higher efficiency at lower costs without sacrificing voltage tolerances or durability.

Transformer cores are an essential component of power transformers. Their contribution to energy efficiency and overall cost reduction is undeniable. Manufacturers are continuously conducting research and development into the production of more energy-efficient transformer cores, and with the current trend, the future of transformer cores looks very promising. The importance of visibility, traceability, and accountability in the production of transformer cores must be considered and is essential for ensuring that the quality of a produced core is up to the required standards.

Visibility

You’ll never see everything that happens in your factory, so it’s unrealistic to outfit an entire facility with cameras. You can bring visibility to everyday activities by leveraging data points that capture information from manual entry, automatic logging, and other sources.

Traceability

Regardless of their industry, manufacturing companies are fast embracing traceability as a vital aspect of the manufacturing process. The concept of traceability should be part of the process of every manufacturer, regardless of whether they produce food, automobiles, or airplanes.

How does the traceability of products affect quality management, especially in manufacturing?

A traceability system aims to connect the physical flow of items with the flow of information and guarantee complete recording of all manufacturing and supply chain phases. The traceability system determines and stores all quality-relevant data from all manufacturing phases in a traceable manner. Businesses can easily and quickly determine how, when, and by whom their products were made, how many suppliers they used, and who received the finished goods by using this system.

Robust traceability systems automatically link data from internal data sources, such as supplier and customer databases, and external data sources, like logistics procedures, IOT, and robots (goods receipt, inventory, goods issue, production control). This guarantees the traceability of the goods and their quality. The systems promote product and process quality, boost productivity, and cut costs to achieve this goal. They also prevent manufacturing errors. If a product failure occurs, the client can instantly recall all impacted batches because the cause of the issue can be quickly found.

Accountability

Accountability is crucial to any successful business. You can build a clear picture of ownership with the information of who did what and when. Mapping out responsibilities to a granular level with specifics down to the person and capturing details depicting adherence to process and procedure can be done.

The Importance of Visibility, Traceability, and Accountability in Energy Efficient Transformer Cores

Visibility ensures that designing and assembling the transformer core is easy to follow. An accessible and transparent production process makes identifying potential errors easier and ensures that the transformer core’s quality meets the required standards. The production process’s traceability ensures that the core parts are sourced from reliable and trusted suppliers. As a result, the quality of the components used to assemble the transformer body directly impacts its performance.

Having traceability also makes it easier to identify the source of any potential faults in the core. Having a record of each step in the production process and access to the materials and components used in the body makes it easy to pinpoint the cause and locate any potential faults. The importance of accountability comes into play in the event of any failure in the transformer core.

The Significance of Energy Efficiency Transformer Cores

The goal of producing energy-efficient transformer cores is to reduce the amount of electricity consumed while delivering sufficient power to the user. This has several advantages. Firstly, the energy efficiency achieved through transformer cores helps to reduce the demand for energy sources such as natural gas, nuclear power, and coal. This helps reduce the pollution and greenhouse gas emissions released into the atmosphere. Secondly, energy efficiency helps to reduce overall electricity costs for the consumer. Reduced power consumption significantly reduces the user’s electricity costs, enhancing other aspects of life and raising the standard of living.

The Future of Energy Efficient Transformer Cores

The development of innovative manufacturing techniques that minimize the amount of power wasted during energy transfer is made possible by several technological developments. Energy efficiency is the current trend in transformer core production. Manufacturers are also focusing on producing transformer cores that are easily traceable and have visibility throughout the production process. The future of transformer cores looks promising as the industry moves towards more energy-efficient technologies. Research and development in manufacturing transformer cores will improve efficiency and dependability.

Being a producer of energy-efficient transformer cores, Corefficient gives its clients a competitive edge by producing the highest caliber of electrical cores that consistently satisfy their quality, delivery, and value standards.

We are committed to providing our customers with the best products and services. We aim to provide a safe, reliable product through superior customer service.

With over ten years in the transformer industry, we have gained extensive experience in testing, inspection, and repairing metal core transformers. We have also invested in the latest equipment to ensure that we meet your needs whether you require small or large quantities of cores.

Our core testing facility is ISO-certified and NRCAN-approved. We adhere to DOE regulations and ASTM standards for quality control of our products before shipment to customers.

More About Corefficient and Their Energy Efficient Cores

Corefficient, a transformer core supplier based in Monterrey, Mexico, offers the market value of people, technology, and financial strength. A key component in creating dry-type and liquid-filled transformers, Corefficient designs, produces and sells energy-efficient transformer cores. We aim to provide excellent service consistently, and the business is excited to create a new legacy based on value.

Please visit our website or call our North American sales engineer at (704) 236-2510 if you’d like to contact us.

Corefficient at CWIEME Berlin 2023!

Image attribution: https://berlin.cwiemeevents.com/page/press